Selection of Low Dielectric Constant Fiberglass Material for Blended Fabrics

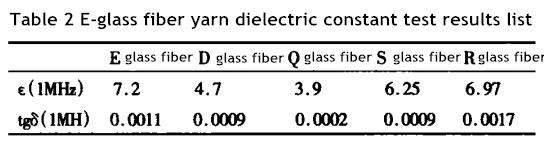

As 7628,2116,1080 and other electronic fabrics are used to make copper-clad reinforced textile electronic materials, warp and weft yarns are silicate glass with the material in the high-temperature conditions through the physical and chemical reaction of the silicate, Through the drain pull drawing made of glass silicate with different composition of the textile glass fiber has a different dielectric properties. Dielectric density and polarization rate of the dielectric constant of the size of the main factors, such as E means the glass fiber, D means the glass fiber, Q means the glass fiber, the dielectric properties of the measured as shown in Table 2.

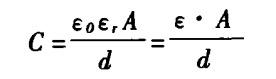

As can be seen from Table 2, compared to D glass fiber and Q glass fiber and E glass fiber , D, Q glass fiber has excellent dielectric properties, is our ideal material when we match low dielectric constant insulation material. But they all have two major shortcomings: First, poor machinability, in the hole process of high-speed PCB drill wear large; Second, D glass fiber, Q glass fiber ‘s manufacturing costs are higher than the E glass, the price of the E glass Fiber cloth is more expensive than the price of D glass, so it is not suitable for commercialization. In order to be able to better solve the economic benefits for the purpose of industrial production needs, In order to be able to better solve the economic benefits for the purpose of industrial production needs, to play E, D, Q and other glass fiber their technical and economic performance advantages of different varieties of glass fiber for a reasonable matching requirements, both to ensure good Low dielectric properties, but also a good solution to the problem of the cost of industrial production, to seek an optimal proportion of the best blended components, is one of the main problems we need to study. If we ignore the edge effect of electronic cloth, that the electronic cloth is a parallel plate capacitor, and its capacity can be expressed by the following formula:

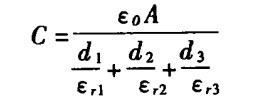

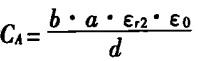

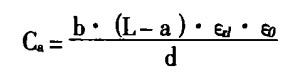

Where: A for the plate cover area (m2); d is the distance between two parallel plates (m); ε is the permittivity of the medium between the plates; εr is the relative permittivity of the medium between the plates; ε0 is the dielectric constant of the vacuum (= 8.85 x 10-12 F / m). In the above formula, ε, A, d three parameters, as long as the two remain unchanged, when change one of the capacitance ,then C can changed, then for the copper clad laminate, to use of plates other than the medium In addition to air , due to the dielectric constant of the different media, you can change the capacitance between the plates, when ignoring the border effect, the capacitance can be expressed as:

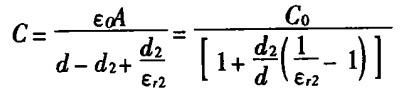

Where: whenεr1=εr3=1 is air medium, and d=d1+d2+d3, then:

Thus, the solid dielectric capacity

And Air dielectric capacity

Where: b, L, d,is respectively for the plate width, length and distance between the plates; C0 is the initial medium capacitance when all the plates is full of air medium.

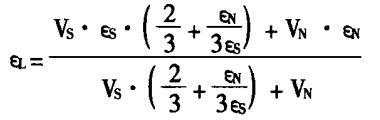

Similarly, for the two-in-one ratio of low dielectric constant glass fiber blends fabric dielectric constant determination, you can derive the following function.

εl is the dielectric constant of the blended fabric, εn is the dielectric constant of the A-component glass fiber material, εs is the dielectric constant of the B-component glass fiber material, εn is the volume fraction of the A-component glass fiber material, Εs is the volume fraction of the B component glass fiber material.

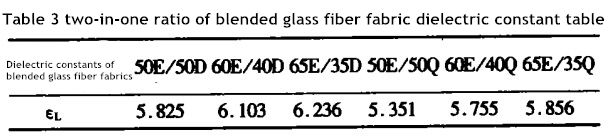

From the above equation, a low dielectric constant blended fabric substrate material, which blended fabric glass fiber material volume percentage has a close relationship.The development of such substrate materials technology also shows that the development of low dielectric constant substrate material, from both hands and development, namely the development of low dielectric constant glass fiber materials, on the other hand through scientific selection, Low-ε of the textile reinforcement material spinning ratio, the two items are the key effective to solve the development of high-performance low-dielectric low-frequency high-frequency questions.For example, the choice of E-glass fiber and D glass fiber blending, the use of various ratios to seek the best test results to determine, such as 60/40, 65/35, 70/30, 80/20, 85/15 combo ratio Relationship or three-in-one ratio scheme, carry out scientific experiments and optimize the test results to determine the best blending ratio relationship, weaving and then weaving can be obtained after many varieties of low dielectric constant of the enhanced fabric, meet the technical requirements of high-speed electronic products ,As shown below.

Through the above research, we can find the most suitable blended fabric with low dielectric constant for high frequency CCL, this method can meet the technical performance requirements, but also reduce costs, it is necessary to conduct systematic research.

Conclusion

It can be concluded that spinning with two or three in one relationship can solve the electrical properties of low dielectric constant blended fabric; But also a good solution to reduce the cost of glass fiber materials.

On the surface of blended 7628 fabric coated with a lower dielectric constant of PTFE (ε = 2.1) or other components of the resin material, using finishing technology to deal with the fabric, to reduce the high-frequency CCL dielectric constant effect is also very good.