Fabrication Process and Electrical Property Analysis of 7628 fiberglass cloth

Weaving fabric 7628, in accordance with the process design requirements are warp with 68tex, weft is also 68tex glass fiber twist yarn, the total reed width is 102cm; the Within deduction is 101 cm; Reed No.is 87 #, 2 penetration; The number of warp roots is 1758; Edge reed number is 100 #, 0.5cm × 2.2 penetration; The number of the side root is 10 × 2 = 20; The total number of roots is 1778; Warp dosage is 120.9 g / m; Fabric is plain weave; Weft density is 12.6 root / cm; Weft amount is 87.4 g/m, the total amount of yarn is 208.3 g / m, Loss of yarn volume is 0.3% (215 g per meter); If the shuttleless air-jet loom weaving, the process requirements are: Warp: raw materials – warping – fishing reed; Weft: the original latitude used directly, if tension was not uniform, then take the reel ,Fabric organization structure with a top-down plain weave, Shaped the requirements of smooth surface, even dry, less hairiness, no shortage of stocks and other phenomena, Weaving the latitude and longitude when asked to highlight the point, full of particles, such as the lack of dense road weaving defects, smooth cloth was Lo-like to meet the multi-layer or thin layer of rigid copper clad laminate technology requirements. In order to obtain a clear fiberglass yarn and 7628 cloth fabric microstructure, more direct observation of the original yarn and fabric structure of the appearance of the image and the electronic scanning to take pictures. As shown in Figure 1, Figure 2 (JSS-1 type instrument using electronic scanning microscope, the original yarn, the fabric surface by spraying gold and then imaging).

Figure 1 Photomicrograph of glass

Figure 2 7628 fiberglass cloth micrograph

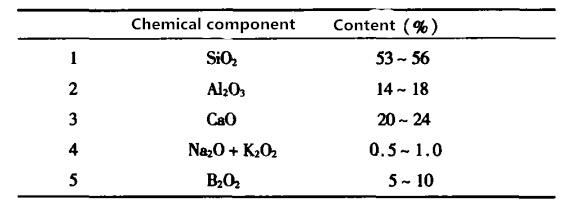

At present, the world’s production of silicate glass fiber fabric composition is roughly the same, The basic components are SiO2, Al2O3, CaO ternary system. The weight percentage fluctuates only within a small range, as shown in the following figure.

Figure silicate glass composition formula

Factors Influencing Dielectric Properties of Silicate Glass Fibers, Most scholars believe that the general silicate glass is ion conductivity, at room temperature constitute a glass network of silicon oxygen or boron oxygen, aluminum oxygen skeleton is almost non-conductive. However, when the network is filled with cations, in particular when the alkali metal ions are charged, the cations bound by the ion bonds have a certain mobility so that become a weak conductorand they are the main factors affecting the electrical insulation properties of glass. The migration ability of monovalent metal ions in glass is often affected by the extent of glass breakage, the size of the cation itself and the repression of other cations R2 +, R3 + and R4 +. The more network bonds are broken, the more likely the cation radius is to migrate, The order in which a monovalent alkali metal ion reduces its resistance in glass can generally be attributed to: K2O

In this kind of glass metal ions in the transfer of current, in which the alkali metal ion transport capacity of the largest alkali metal oxides are the main factors affecting the electrical insulation properties of glass, Silica radicals or boron oxygen ions in the current under the action of no mobility, so in order to improve the electrical insulation of glass, it is necessary to reduce the glass alkali oxide content; In the non-alkali aluminum borosilicate glass, in order to ensure the electrical insulation properties of glass fiber as electrical insulation materials, the vast majority of countries are required E glass fiber R2O content should be less than 1%, generally below 0.8%. If further reduced the R2O content, the actual use would have no significant improvement. On the contrary, the choice of raw materials and glass melting on the trouble and difficulty, from the economic sense is not necessarily reasonable, so the manufacture of low dielectric constant glass fiber material must pay attention to the regularity of insulation performance.

![]()

General CCL substrate material is made by the polymer resin, resin additives, fillers and reinforcing materials (fiber paper, fiberglass cloth, glass fiber non-woven fabrics, etc.).Such an electrical insulator is also called a dielectric.The ratio of the capacitance of a capacitor which containing a dielectric material to its capacitance in vacuum (C / C0, where C is the capacitance of the dielectric capacitor and C0 is the capacity of the vacuum capacitor) is called the dielectric constant (ε) of the dielectric material.It can be seen that the dielectric constant is a multiple of the capacitance of the dielectric capacitor and the capacity of the vacuum capacitor, and it shows, on a macroscopic scale, the ability of the material to store electrical energy.We can think of any substrate material of electronic product as a capacitor in the entire PCB circuit. When its ε is large, its stores energy capacity will become strong on the circuit, the electrical signal transmission speed will become low,The current direction of the electrical signal through the PCB substrate, generally constantly changing (positive and negative alternately), this frequent interchange, is constantly on the substrate material “charge – discharge” process, in the swap , As long as there is little capacitance to stay, it will affect the PCB substrate electrical signal transmission speed.This effect may be negligible for PCB designs in general electronics, but it is important for PCBs that require high-speed transmission of information processing devices. From the formula can be seen that the circuit signal transmission speed V (m / s) and ε have a great relationship:

![]()

Where V is the speed; K is constant; C is the capacitance; ε is the dielectric constant. In the formula, when ε is larger, the V is lower, that is, the transmission speed is reduced. The ε value (ε = 2.6) is 47% lower than the ε value (ε = 4.9) of the epoxy resin substrate if the fiberglass base is a fluororesin base material. So the use of the former PCB substrate signal propagation speed 40% faster than the latter; so it can be said in the high-speed transmission of information processing device in the dielectric constant is one of the key technical issues can not be ignored.

If you want to know more about the product information, please fell free to contact us system@corefrp.com, we have a dedicated technical engineers to answer your questions, and we provide free sample service.