Force Analysis of Weft Yarn in Weaving 7628 fiberglass Cloth During Nozzle Blowing

Electronic glass fiber cloth is the composition of aluminum borosilicate, commonly known as E-glass, the international referred to as E-glass, that is insulating glass.Alkali-free glass refers to aluminum borosilicate glass in which the alkali metal oxide content is less than 1%. This glass was originally developed for electrical applications, but the application has far exceeded this, it has almost become a common glass formulations, the number of applications has been the world’s total output of continuous glass fiber 80% -90 %.E-glass fiber electrical insulation performance is very high at room temperature, its volume resistivity is greater than 1015Ω • cm, the frequency of 106Hz dielectric loss angle tanδ is 1.1 × 10-3. The dielectric constant ε is 6.6 Was 6.6. E-glass fiber also has a high strength, its new ecological unit strength can up to 3.5 Gpa, elastic modulus is730 Gpa.At present, the above-mentioned non-alkali glass fiber to the manufacture of copper clad laminate in the electronics industry,At present, there are three kinds of main specifications in electronic grade fiberglass cloth , the largest amount of which is known as the 7628 cloth, its nominal thickness is 0.173 mm, the mass per unit area is 204.4 g / m2; the second specification is called 2116 cloth, its nominal thickness is 0.094 mm, the mass per unit area is102 g / m2,A slightly smaller amount is called the 1080 cloth, its nominal thickness is 0.053 mm, the mass per unit area is 46.8 g / m2. Recently, there is a gradual increase in the amount, its known as the 7629 cloth, its nominal thickness is 0.18 mm, the mass per unit area is 213 g / m2, the processing looms for production 7628 fabric are mostly air-jet weaving Machine, because for its fast speed, less yarn defects, high economic efficiency and has been accepted by the majority of the world’s textile enterprises,But for different kinds of fiberglass fabric, can the weft weaving in the loom be successfully completed weft, beating and other processes, and ultimately weaving the requirements of the copper clad laminate fabric is the subject which we need to seriously study .

Fiberglass weft flying to a large extent determine the fabric quality of 7628 cloth. The so-called fly-off is the weft in the air-jet loom on a certain air pressure and air flow conditions, in a certain period of time the amount of weft yarn and yarn-shaped structure of the technical indicators. The Flyaway of the weft yarn is closely related to the attachment rate of the infiltrating agent on the precursor and the stiffness of the twisted yarn. Production practice has proved that the attachment rate to (1.0 ± 0.2)% for the good, stiffness to 100 ± 15 best. Usually 7628 fabric woven adopted by air-jet looms, the cloth of the latitude and longitude density of 42 × 32 / 25mm, package volume per axis length of 1000-2000 m, in order to make the weft during the jet weaving process with the required stiffness, To achieve a certain degree of flying, the original wire in the drawing process, the amount of sizing agent must be appropriate, the original silk in the process of hot air drying temperature and weaving process of temperature and humidity must be strictly controlled, At the same time, the weft of the air-jet loom flight speed should be as close as possible to the air speed, but also requires the weft yarn flow rate is always higher than the weft yarn flying speed, Thus ensuring high-speed weft flying, shortening the filling time of the weft, but also to ensure that the weft yarn end in the shed to maintain a very direct flight to improve the quality of jet weft and increase the weft insertion width, providing good conditions, so as to ensure that 7628 Cloth in the weaving process of the appearance of defects to a minimum, an average of not more than 7.5 per 100 meters of the main appearance of defects. The unit area quality control is (205 ± 6) g / m2 in the first class and (205 ± 4) g / m2 in the second class. As the air-jet looms are generally high-speed weft, weft storage devices are used, so that all types of shuttleless loom raw materials and fineness of the adaptability has been increased, however, in the passive weft insertion mode, the filling range of the weft fineness has some limitations, Usually air-jet loom adapt to the range of 8.3-100 tex (10-120 public support), flat and deformed filament fibers adapt to the range of 4.4-44.4 tex (40-100 tex). How to control the weft tension of weft yarns of different fineness and make the weft insertion tension of different typical characteristics to be scientific and reasonable, It is assumed that the fineness of the glass fiber yarn is 1 tex, the length of the yarn to be accelerated by the jet weft insertion is L, the mass of the yarn is m, the weight of the yarn at the specified moisture regain rate Wk is Gk, and the mass of the yarn from Ntex = Gk × 1000 / L is m = L / 1000 × g, the kinetic energy of the yarn is:

![]()

(Formula 1)

In the braking stage, the yarn segment L by the extension of the work done are:

![]()

(Formula 2)

(2) where it is assumed that any point in the yarn segment L, the aerodynamic thrust of the yarn produced by the stress:

![]()

(Formula 3)

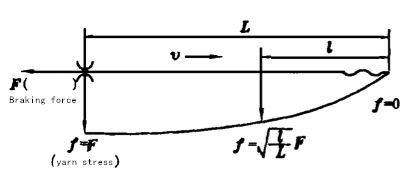

The force analysis shown in Figure 1.

Simplified formula (2) available

![]()

(Formula 4)

在制动阶段,纱线的动能与纱线段L伸长而作的功相平衡,所以(1)式与(4)式相等,由于g=9.81/m2,可近似地认为g=10/m2,估得:

In the braking stage, the kinetic energy of the yarn is balanced with the work done by the extension of the yarn segment L. Therefore, (1) is equal to (4), g equal 9.81 per square meter,estimated:

![]()

![]()

(Formula 5)

Figure 1: Glass fiber weft force analysis

In the Formula : F is the breaking strength of weft yarn (CN / Tex); V is the speed of the yarn (m/s), E is the elastic modulus of weft yarn (CN / Tex) L is the yarn length (m); ƒ is the yarn strength (m / Stress (CN / Tex); and m is the yarn mass (kg).The actual measured weft tension is less slightly than the above calculated value, because the calculation assumes that there is an acceleration process for the jet weft yarn on the yarn.At the same weft insertion speed, the longer the time of this acceleration process, the smaller the peak value of the impact suffered by the yarn.It can be considered, to make the glass weft adapt to high-speed shuttless loom high-efficiency weaving, one is to make the average breaking strength of glass fiber weft to maintain a certain level, the use of fiberglass weft should be a certain degree Stiffness, so that the glass weft to ensure that the straight in the shed can be in the flight; the second is to strengthen the glass fiber drawing, twist and other processes of production control to reduce the glass weft breakage rate in the weaving process.

If you want to know more about the product information, please fell free to contact us system@corefrp.com, we have a dedicated technical engineers to answer your questions, and we provide free sample service.