Influence of Different Treatment Methods of Glass Fiber Surface Coupling Agent on the Properties of Resin Matrix Composites

The Microscopic Appearance of Glass Cloth

Scanning electron microscopy was used to observe the microstructure of glass cloth produced by A and B manufacturers, as shown in Fig 1. It can be seen from the figure, A, B two manufacturers of glass fibers were not found defects or damage, no significant difference in micro-morphology. Two kinds of glass cloth physical and chemical properties, appearance quality, or less.

(a) A factory

(b) B factory

Fig.1 Microstructure of glass cloth

The Wettability of Glass Cloth

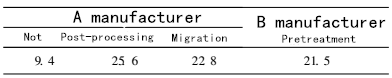

Glass fiber surface coupling agent treatment is generally divided into three methods.(1) Post-treatment method: first to remove the textile-type sizing agent, and then impregnated with coupling agent;(2) Migration method: the coupling agent directly added to the resin solution, dipped in the coupling agent from the glue inside the glass fiber surface migration;(3) Pretreatment: Glass fiber drawing and the use of textile contain a coupling agent, such as infiltration agent treatment.

Two manufacturers of glass cloth after dewaxing treatment, The glass cloth (A cloth) of A factory was treated with KH-560 coupling agent by using post-processing method and migration method. Test the wetting performance, see Table 1.

As can be seen from Table 1, B manufacturers of glass cloth (B cloth) infiltration time is far less than the A cloth, indicating that B cloth is more likely to be resin infiltration. That’s the reason why B manufacturers of glass fiber processed through the silane coupling agent treatment, silane coupling agent is the main treatment of glass fiber surface treatment agent. The structural formula can be expressed as AxMBy. A is an organic functional group which can react with the polymer chain, such as epoxy, ester acyl, etc .; M is the central atom S I; B is a hydrolyzable group capable of chemically reacting with an inorganic material or adsorbed on the surface of the material, which is usually an alkoxy group, and halogen. There are many capillary pores in the glass fiber fabric. If the adhesion of resin to glass fibers per unit length was greater than the capillary force, the resin would pass through the capillary between the fabric fibers, without a large number of bubbles in the capillary. This requires fiber and resin compatibility is good, strong bond. If the capillary pressure was greater than the adhesive force between the two phases, the resin infiltration rate is too low, the air would be sealed in the capillary to form bubbles, not only difficult to exclude, but also resin / fiber interface adhesion will be greatly reduced.

After the A cloth was treated by the post-treatment method or the migration method, the wettability was not significantly improved as compared with the glass cloth which was not treated with the coupling agent, mainly because the glass fibers had formed a knitted fabric, Glass fiber surface is smooth and even reaction or adsorption.And the use of post-processing method or migration method will increase the production process of reinforced plastic ,to improve production costs and reduce production efficiency, so the use of pre-treatment of glass fiber glass fiber reinforced plastic molding is very beneficial.

Microstructure of glass fiber reinforced plastic after ablation

With A, B cloth molding FRP products, Microstructure of ablation test specimen surface with scanning electron microscopy after ablation.

(a) A fabric 400 ×

(b) B fabric 300 ×

F ig. 2 Surface m orpho logy o f ab lated FRP

The scribe region in Fig. 2 is analyzed by EDS, As shown in Fig. 3 (a), it was found that the main component of the layer in Fig. 2 (a) is C. Because the glass fiber reinforced plastic products after ablation, the surface of the organic resin has been completely carbonized, the formation of carbon layer. As shown in Fig. 3 (b), the main component of the pillar in Fig. 2 (b) is Si.

F ig. 3 Ingred ient o f ab la ted surface

It can be seen from Fig. 2 that the carbon layer on the surface of the ablation test piece of the A-cloth forming fiberglass has the whole groove of the glass fiber falling off and the residual amount of the glass fiber melt is very low, which indicates that the adhesive force of the glass fiber and the resin interface is too weak, Ablation of glass fiber melting high viscosity liquid can not effectively play the role of insulation and the protective effect of the carbon layer, when the carbon layer easy to peel off, ablation prone to layer phenomenon; and B manufacturers of glass fiber and The resin is fully bonded and the fiberglass melt is filled into the char layer to densify the ablative surface layer.

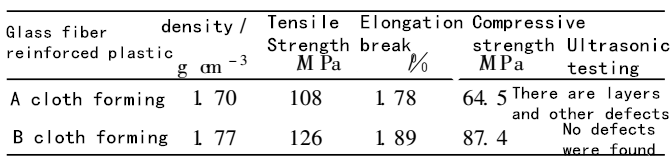

Effect of fiber surface treatment on the properties of composite materials

The density and the like of the glass phenol / aldehyde composite material product were measured by forming the glass phenol / aldehyde composite material with the A cloth not treated with the coupling agent and the B cloth treated by the pretreatment method,2The results are shown in Table 2. As shown in Table 2, the glass fiber reinforced plastic products made of A-cloth have defects such as delamination. The B-shaped FRP products are not found in the interior, and the mechanical properties are better than those of the A-cloth. This is mainly because the fiber surface After coupling agent treatment, the wettability between the resin and the fiber can be improved, and the bonding force between the interface and the interface can be improved, and the comprehensive performance of the composite material can be improved remarkably. it can be seen, fiber / resin interface excellent performance of glass fiber reinforced plastic composite products with high performance.

Tab. 2 Property test results of two types of FRP m ade from different GF cloth

Conclusion

The pre-treatment of the coupling agent can improve the wettability between the fiber and the resin and improve the adhesion between the interface, significantly improve the glass cloth on the resin infiltration performance, while reducing production costs and improve production efficiency ; The use of post-treatment or migration treatment, the glass cloth of the wetting performance did not significantly improve.

strong glass fiber and resin interface bonding ,It can significantly improve the ablation of glass fiber reinforced plastic products.

By the coupling agent before the treatment of glass cloth forming glass fiber reinforced plastic products,it has excellent mechanical properties, and its quality significantly improved.

If you want to know more about the product information, please fell free to contact us system@corefrp.com, we have a dedicated technical engineers to answer your questions, and we provide free sample service.