Discussion on the Production Technology of Glass Fiber Cloth and Application

At the year 1930,the glass fiber company of United States “Owens Corning”produced E glass fiber.Since then, the human achieved the industrial production that take the ore raw materials melting into glass fiber by high temperature.In 1946, China also produced a bundle of glass fiber by using clay pot crucible, then the news reports said<

Electronic grade glass fiber cloth production process

Conventional glass fiber products include: alkali-free glass fiber yarn, alkali-free glass fiber cloth, alkali glass fiber yarn, alkali glass fiber cloth, their production process is basically the same. Taking glass fiber products as an example, the problems in the production process and their solutions are discussed.

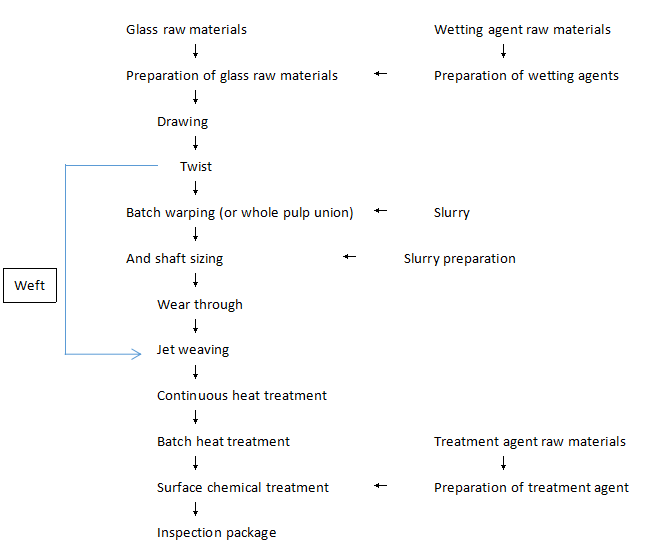

Printed circuit board with electronic grade glass fiber cloth, also known as alkali-free glass fiber cloth, it is the alkali metal oxide content of less than 0.8% of the aluminum borosilicate glass fiber cloth.Electronic grade glass fiber cloth technical requirements are extremely strict, and thus become a modern glass fiber textile technology level embodies. The requirements of the use of glass fiber yarns with sufficient flexibility and spinnability, the textile process and the traditional cotton textile process is similar to the current use of high-speed, low twist, large package twisting process, And the axis of the way to produce weaving axis,single weft high-speed jet weaving.EWPC173-130 (7628), an area density of 204.4 g / m2, and a yarn density of 68.7 for a printed circuit board with an international commercial code of 7628, a nominal thickness of 0.173 mm and a width of 130 cm Tex, twist 28 twist / m, single fiber diameter of about 9μm, warp and weft density of 42 / (25mm) × 32 / (25mm), the specific production process shown in Figure 1.

Figure 1 glass fiber cloth production process

7628 fiberglass cloth production process and cotton products similar to the focus need to focus on the following processes:

(1)drawing:The first to configure the appropriate sizing agent in the original silk evenly film to reduce the original hairiness and improve the efficiency of weaving production.The main purpose of the wire drawing is to maintain the uniformity and stability of the linear density of the original silk, both to ensure that the electronic grade glass fiber cloth Of the surface density and fabric thickness of the uniform and stable, and will not make the fabric surface serious hairiness, resulting in the phenomenon of rubber particles on the surface of the fabric and seriously affect the performance of the fabric.

(2)post-processing:The role of the post-treatment process is to glass fiber fabric in a certain production conditions, a certain temperature heating, so that the coating of the infiltration of the decomposition of components, carbonization, combustion and removal.These wetting agents must be removed from textiles woven from woven fabrics of textile type, since they hinder the adhesion of glass fiber fabrics to resins, rubbers and other substances. The post-treatment process includes continuous heat treatment, batch heat treatment, surface chemical treatment,For continuous heat treatment, the key is to correctly set and control the high temperature desizing furnace furnace temperature and speed, the key to the process is to master the treatment temperature and time, the purpose is to remove most of the organic matter on the cloth, the residual organic matter Reduced to below 0.5%.In general, the processing temperature of electronic grade glass fiber cloth is not higher than 450 ℃ is appropriate, furnace temperature and speed setting and adjustment of the purpose is to achieve the process requirements of organic residue indicators, and minimize the loss of strength.After the heat treatment of electronic grade glass fiber cloth also through the surface chemical treatment to improve the glass fiber and resin bonding interface, improve the mechanical properties of composite sheet and electrical properties. Electronic glass fiber cloth surface chemical treatment of the basic method is the use of silane treatment agent (also known as coupling agent) treatment, and finally dried into a cloth roll, the inspection and packaging to be electronic grade glass fiber cloth products.

Key technology of electronic grade glass fiber cloth production

The key to the post-treatment process of the electronic grade glass fiber cloth is the index of the residual amount of the organic matter in the heat treatment. If the indicator is too high, the yellow and black lines may appear on the cloth. This phenomenon will not only affect the appearance of the fabric, but also seriously affect the conductive rate.In the surface treatment process, if the coupling agent solution is unstable, it will seriously affect the bonding of the electronic grade glass fiber cloth with the resin. In the electronic grade glass fiber cloth production process there is an important problem, that is, the weft yarn weft skew, which is mainly woven and post-processing process through the guide roller is not parallel to the resulting, and ultimately will cause electronic grade glass fiber Cloth warp.

The appearance quality of the electronic grade glass fiber cloth, such as the occurrence of weaving defects and cotton fabrics are basically the same. According to the characteristics of glass fiber,Electronic grade glass fiber cloth in the production process should pay attention to the following three main issues:

(1) the use of as little as possible the number of processing;

(2) the process line as much as possible to reduce the bending and friction of glass fiber;

(3) the process of maintaining a uniform tension, which is particularly important for glass fiber cloth.

Electronic glass fiber cloth market prospects

The electronic grade glass fiber cloth is an indispensable material for copper clad sheets and is the basis material for printed circuit boards. Printed circuit board is a high-tech products of the electronics industry, and multi-layer printed circuit board is the most representative,the most productive and development potential of the electronics industry.In recent years, with the electronics industry towards high precision, high density, high performance, micro-hole, thin and high-level direction, the major electronic cloth manufacturers have to take appropriate effective measures to maximize the elimination of electronic cloth Trace metal impurities, reduce the micro-bubbles in electronic yarn, improve the smoothness of electronic cloth and resin impregnation, so that copper-clad copper plate with electronic grade glass fiber cloth to achieve a high precision, high uniformity, high purification and high stability and many other Claim.The application of electronic grade glass fiber cloth has been rapidly entering the industrial sector from civilian appliances and related products such as televisions, mobile phones, laptops, mini-cameras and storage cards. China has long been the electronics industry as a pillar industry of national economic development, printed circuit boards and copper clad sheet is considered the basis of the electronics industry, and electronic glass fiber cloth is the pillar industry is essential to the basic material.

The international electronics industry to digital technology and network technology as the representative of the information technology continued to leap year by year, a large number of electronic information products upgrading (such as the further promotion of digital television applications, etc.), making the new market demand continues to emerge. With the rapid rise of the international electronic information industry, greatly promoted the electronic glass fiber cloth market prosperity, market demand growth year by year, electronic glass fiber cloth market prospects are very broad.

For more information, Please contact us at system@corefrp.com. Our technical service representative will at your service!

Discussion on the Production Technology of Glass Fiber Cloth and Application.pdf

Discussion on the Production Technology of Glass Fiber Cloth and Application.pdf